Specialised Services

Project Management

The combined knowledge and know how of the project management team is significant. All projects create a real sense of comradery. The process of leading a large team is set down from the start with clear objectives and carried on through to monitoring progress and performance regularly. This is a company which has the momentum and track record to carry out large scale engineering and pipeline works across New Zealand.

Pipeline Construction

Warner’s substantial pipeline construction capabilities are found in multiple work shops located in New Plymouth and Taupo. The premises include specialist facilities for modern Plasma Cutting machines, and Sub Arc Welding works. Warners pipeline capacity works is impressive; they have recently fabricated and installed a 15km (approx) pipeline at the Tauhara Steam Field in Taupo, in the Central North Island of New Zealand. Efficiency and reliability with world class safety standards have ensured Warners ongoing projects in the fast-paced and growing renewable energy sector to continue.

Geothermal

The majority of Warner Constructions Geothermal and Hydro works have historically been for Contact Energy and Mercury, however they will fabricate and install any engineering related projects anywhere in New Zealand.

Over the last decade Warner’s reliability and quality of works have enabled them to dominate key projects for the majority of geothermal pipeline works in Taupo and the greater Bay of Plenty region of New Zealand. Warner Construction have recently completed their largest pipeline project for Contact Energy - the Tauhara Steamfield, and warmly invite you to view their Geothermal projects portfolio.

Workshop Fabrication

Warner Construction have invested in state of the art fabrication machinery and welding services to fulfil the industry needs for more efficient multi-disciplined civil and mechanical projects.

To find out more of what’s on offer please click below:

Civil Construction

Culverts, trenches, drain line systems including drain-lines, drain-pits and culvert ponds

Well-head stinger and thrust frames

Pipe shoes, supports and associated foundations

Platform and pipe support foundations

Reinforcing pads

Silencer vessels and foundations

Retaining walls

Bike walkways

Access stairs

Stainless Steel and FRP security fencing

Bulk earth works

Live line excavation and investigation works

Plant Maintenance

Plant Shutdown

Scheduled Maintenace

Labour Supply Unit

Hydro Testing

Repairs/Refurbishments

Specialist Workshop Capabilities

Fleet Maintenance

Warner Construction maintain and service all their plant and inventory. Qualified diesel mechanics are utilised for both out in the field and in-house fleet maintenance/servicing.

Warner Construction have the ability to be highly self-sufficient in their working environment. They remain a competitive market leader in the engineering industry because of their multi-skilled workforce and multiple workshop capabilities.

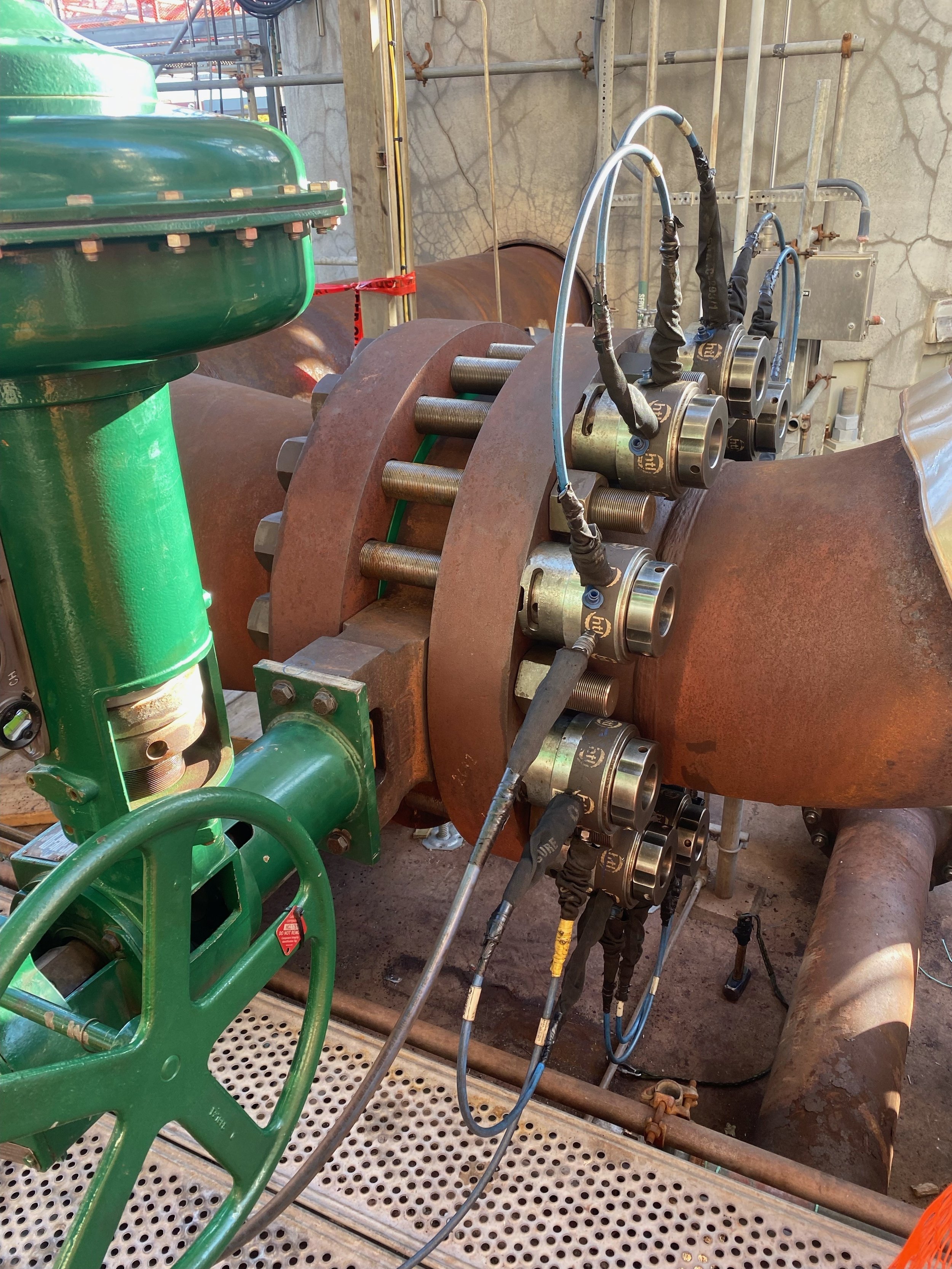

Bolt Tensioning

Pipe and Equipment Installation

Warner Construction have equipped themselves with specialised machinery and operators to tackle all pipeline installs and their diverse portfolio proves that they have the know-how and can-do for the most challenging of briefs. Side boom excavators can mobilise pipe installs of all sizes. Cross-country pipe transportation and equipment installation are carried out with top of the line equipment, allowing Warners skillset to be independent and resourceful for all project machinery needs.

Pressure Testing

Soil Testing

Warner Construction are also equipped with soil testing analysis. The soil testing lab was established in 2015 and has satisfied all requirements of ISO 17025:2005 for IANZ accreditation of field and laboratory sampling and testing. To find out more and how this important data can assist with your next project, please visit Civil Test.